Kempton Steam Museum journal

Yesterday I left for the Kempton at approximately 8AM, aiming to reach the site by 10AM, which is when work ordinarily begins.

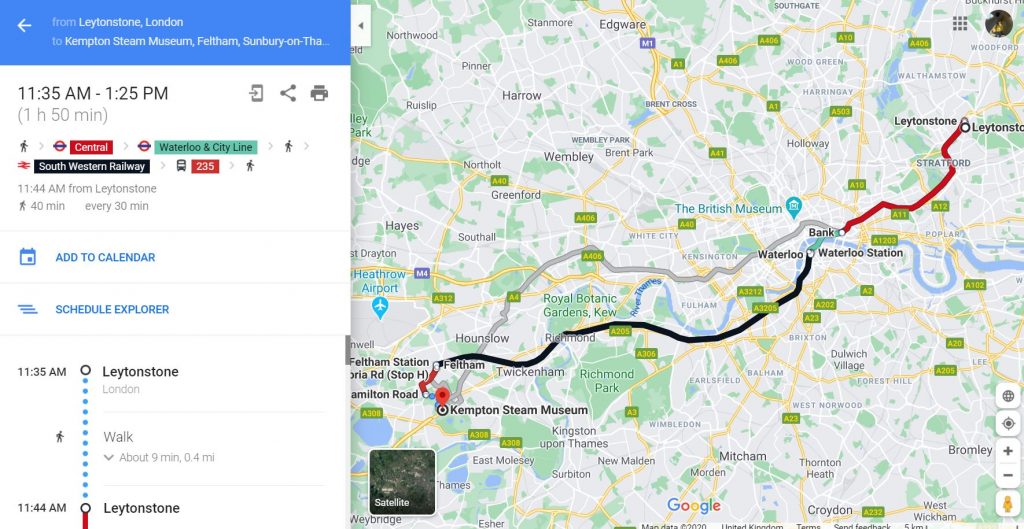

Took the Central line from Leytonstone to Bank (instead of Tottenham) to see if this might be a more efficient route to Waterloo via the Northern line. Annoyingly, it wasn’t. Northern splits into two rails, with only one connecting to the Waterloo train station. Tottenham puts me on the correct Northern side, whereas Bank puts me on the wrong side. Time wasted penalty = 15 min.

Once I get set straight, I reached Waterloo and hopped right onto a departing train to Feltham. Normally I grab a quick Starbucks before boarding the train, but in this case I made use of a portable coffee thermos from the house. No time lost!

I reached Feltham station at about 9.15 and decided to try taking the H235 bus rather than my usual H25 bus toward the museum. Resaon: During my first visit to Kempton back in February, I took the H235 – which was a lovely drive – to a stop called Sunbury. From there, it was about a 30 minute walk along the English country side along Snakey road. I love that route, but I havent been able to find it since. Since then, Google maps has routed me to the H25 bus, which is an ugly journey through Feltham that spits me out along a roundabout next to the highway, and a fifteen minute walk to the museum from there.

Anyways, the H235 bus I took yesterday was not the correct bus, and when I realized I needed to abort, it was a 45 minute walk to the museum. It was a nice walk, but I ended up arriving at the museum at 10.45. Ugh!

Ill get it right one of these days. One thing though, one of the fellow volunteers – John, a quick witted, white bearded, leader in the mechanical team, told me that the bus routes change in Feltham depending on local events, such as horse racing. This may be the cause of all the confusion!

I spent the majority of the day earning the evening’s two cap-off beers at Whitherspoons in Feltham by assisting in clearing out bramble bush and dirt from a storage area, building scaffolding, and hauling about 40 or 50 lengths of galvanized pipe, each about 20 feet long form the museum to the nearby under section of an overpass.

I really got to know a few of the guys this time around. Hard work always breeds discussion to pass the time.

- Richard helped me with the pipes. He is building a car back at home, and has a friend who is building an airplane. Wonderful man, retired from own business selling forklifts.

- John, one of the lead volunteers of the mechanic team. Been volunteering at the Kempton since 2004. He is a born leader, and gets in there with the rest of the boys. At one point Richard prodded John about adding cross bracing to old scaffolding saying it was basically a waste of time. “Trust me when I tell you there will be bracing on this scaffolding, Im afraid Im going to have to pull rank on you”, and that was the end of it.

- Another fellow named John. He came in a bit later to help us with the scaffolding. Apparently this was his field of expertise, and provided guidance and assistance in assembling the scaffolding.

- Dave – a fellow American from Boston. Helped out here and there where he could. Dave offered his advice in obtaining my VISA since he has been there and done that. He also has a vacation home somewhere in Maine, and has some interesting stories.

- (Unknown) Damnit I hate it when I forget names. I think his name is Richard, but then that would mean I know three Richards at the Kempton. Anyways, the oldest of the lot (just about everyone I work with at the Kempton are retired seniors), wore a peddlars cap, and incredible friendly. He works for the rail road “children” as the mechanic team calls them (you see, the Kempton museum includes the steam engine side, and also a railroad side). He was happy to show me an old diesel engine they had underneath a tarp. It was apparently lost in storage under the bridges. The railroad side is planning on rebuilding it soon. He also has a beautiful old white Triumph car in immaculate condition. He showed me the engine. It was an interesting speicmen, as it had an inline 4 cylinder bolted to an inline manual transmission, that somehow routed power back to the front wheels. That is two right angles the power has to be directed through in order to reach the differential.

In other news, I think I’ve worked out the torque generated from the steam engine.

Each engine generates about 1000 horsepower at 25 RPM. According to some websites, the calculation for torques is HP * 5252/RPM (a base point where torque and HP always intersect in graph form).

That is 5,252,000/25 = 210,080 foot pounds.

This doesnt suprise me given how collosal these engines are. Torques is the twisting force, and when you have connecting rods that weigh hundreds of pounds each, swinging a crankshaft that weighs somewhere in the neighborhood of 30 tons, you’re going to get some serious numbers.

Im excited to bring this up to my fellow KSMers.